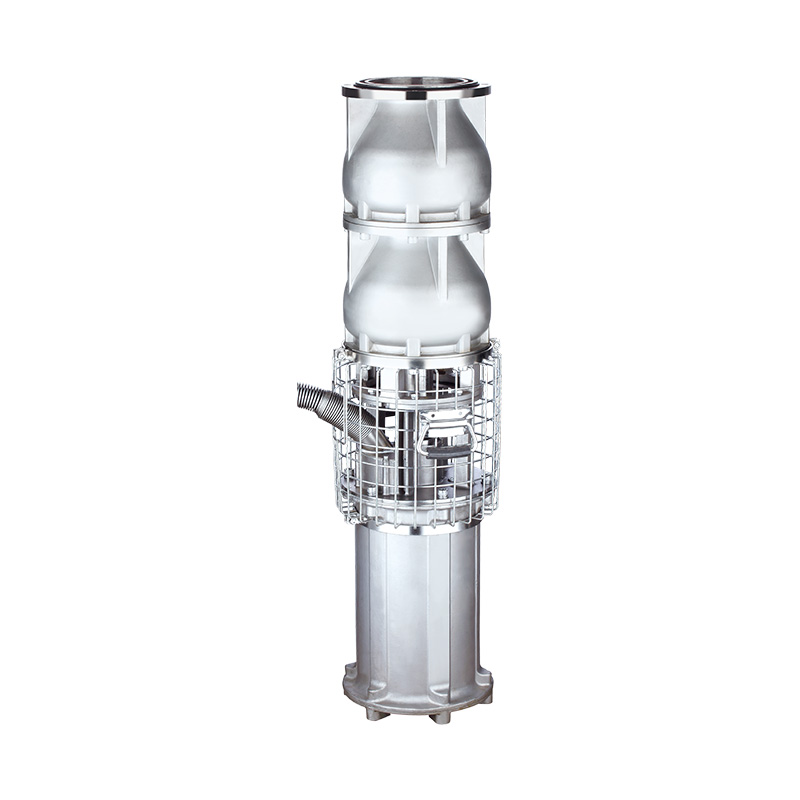

The Stainless Steel High-Pressure Magnetic Drive Pump is a type of centrifugal pump where the transfer of mechanical energy to the pump shaft is accomplished through magnetic fields rather than a direct coupling. This magnetic drive eliminates the need for seals and other mechanical components that traditionally wear out and require maintenance. Constructed primarily from stainless steel, the pump is built for durability, corrosion resistance, and long-term use in demanding applications.

One of the primary ways the Stainless Steel High-Pressure Magnetic Drive Pump contributes to energy efficiency is through its design. The absence of mechanical seals in the pump results in reduced friction losses, which significantly decreases the amount of energy required to operate the system. Traditional pumps often rely on seals that can wear out, friction that consumes excess energy and causes system inefficiencies. In contrast, the Stainless Steel High-Pressure Magnetic Drive Pump uses a magnetic coupling, which results in smoother, more efficient operation.

Additionally, stainless steel’s corrosion-resistant properties ensure that the pump operates at peak efficiency over a longer period. Corrosion can degrade materials, inefficient energy use and the need for frequent repairs. The Stainless Steel High-Pressure Magnetic Drive Pump eliminates this concern, ensuring a longer lifespan and stable performance. The durable construction also contributes to lower maintenance costs, which can otherwise add to the energy expenditure over time.

The key feature of the Stainless Steel High-Pressure Magnetic Drive Pump is its magnetic drive mechanism. Unlike conventional pumps, which require direct mechanical coupling to the motor, the magnetic drive uses magnets to transmit energy to the impeller, which spins and creates the centrifugal force that moves the fluid. This innovative design reduces mechanical losses and minimizes the amount of energy required to transfer fluid.

Magnetic drives also contribute to a more consistent pump speed. When the pump’s motor runs, the magnetic coupling ensures that the impeller operates at a steady speed, reducing fluctuations that can occur in mechanically driven pumps. This consistent speed results in smoother fluid flow and more reliable performance, reducing the risk of overloading the system and enhancing overall energy efficiency.

Another advantage of the magnetic drive is its ability to handle varying fluid viscosities and pressures more effectively than traditional mechanical drives. By optimizing the speed and reducing friction, the Stainless Steel High-Pressure Magnetic Drive Pump can move a range of fluids, from thin liquids to more viscous substances, with less energy required for operation.

Stainless steel is chosen for the construction of the Stainless Steel High-Pressure Magnetic Drive Pump due to its ability to resist corrosion, abrasion, and wear, which is particularly important when dealing with aggressive or abrasive fluids. Corrosion-resistant materials ensure that the pump maintains its efficiency over time, avoiding the need for replacement parts or repairs that could compromise energy performance.

Moreover, stainless steel's ability to withstand high temperatures and pressures allows the Stainless Steel High-Pressure Magnetic Drive Pump to operate in more demanding environments without suffering efficiency losses. This feature is particularly beneficial in industries such as chemical processing, oil and gas, and pharmaceuticals, where pumps are expected to handle a wide range of materials under high pressure.

By maintaining its structural integrity, stainless steel ensures that the pump runs efficiently, reduces the need for frequent maintenance, and extends the lifespan of the pump, contributing to overall energy savings and cost-effectiveness in the long term.